Week 12 - Materials

| Site: | Unitec Moodle |

| Course: | ENGGMG7109 - Resource and Environmental Management 2022 |

| Book: | Week 12 - Materials |

| Printed by: | Guest user |

| Date: | Thursday, 12 February 2026, 3:04 PM |

1. Assessing Green Buildings

"High performance green buildings are defined by the assessment systems that rate and certify them" Kibert, 2013. This actually means that the building scores points according to the design of the assessment system. The criteria for which buildings can achieve their green status is therefore highly variable and often dependent on the country in which it is situated. This is because the assessment criteria often varies on a country by country basis. Within each country, this standardises the approach to sustainable building, however this does make the assessment somewhat subjective to the assessors. For example, some countries would value some attributes to be more important than others. Another disadvantage of this system occurs due to financial and time constraints. Many assessments systems rely on energy modelling to forecast energy consumption to reduce these effects. There can be large inaccuracies in this approach which has led to the finished project having a far greater power consumption than predicted. Another disadvantage of this approach is that consistency is provided at the cost of innovation.

"High performance green buildings are defined by the assessment systems that rate and certify them" Kibert, 2013. This actually means that the building scores points according to the design of the assessment system. The criteria for which buildings can achieve their green status is therefore highly variable and often dependent on the country in which it is situated. This is because the assessment criteria often varies on a country by country basis. Within each country, this standardises the approach to sustainable building, however this does make the assessment somewhat subjective to the assessors. For example, some countries would value some attributes to be more important than others. Another disadvantage of this system occurs due to financial and time constraints. Many assessments systems rely on energy modelling to forecast energy consumption to reduce these effects. There can be large inaccuracies in this approach which has led to the finished project having a far greater power consumption than predicted. Another disadvantage of this approach is that consistency is provided at the cost of innovation.

Try the following links to find out more about green buildings, link 1 and link 2

In NZ, the green star system is used which provides one to six green stars for sustainable buildings. The Geyser building is the first new 6-green star building, based in Parnell, Auckland. The green stars have been awarded based on the following attributes:

- Using nearly a third less energy

- Using half the amount of artificial lighting and water

- Breathing 100% fresh air (compared with 25% in air conditioned offices)

- Accessing a 165 vehicle automated car-stacker (all disabled car parks)

- Using a rainwater harvesting system to store and supply water to the toilets and irrigation system

- Utilising showers, lockers and cycle parks to encourage active transport, as well as being close to major public transport hubs. (data provided by NZGBC)

However the following disadvantages have also been noted:

- The building has no heating system and so electric heaters are used during some months

- The car-stacker has been observed to deliver the wrong car on occasions which increases the energy usage.

1.1. Worldwide green assessment

Most assessment systems have standard categories such as energy, water and indoor environmental quality for rating the building (Kibert, 2013). The following describes some of the assessment systems available globally.

LEED (USA)

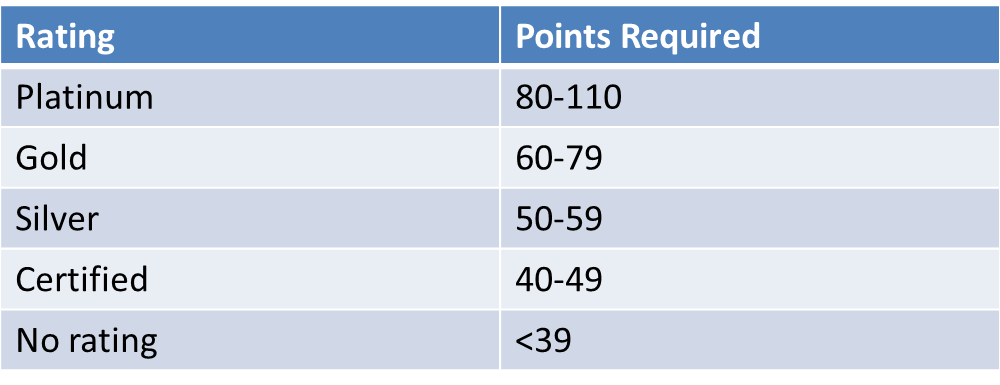

LEED (Leadership in Energy and Environmental Design) is a product of the US Green Building Council (USGBC) and is the most frequently used building assessment in the USA. The primary objective of LEED is to determine "how green is your building?". This assessment standard provides a single number that determines the building's assessment or rating based on an accumulation of points in various impact categories. These categories include: sustainable sites, water efficiency, energy and atmosphere, materials and resources, indoor environmental quality, innovation in design and regional priority. The building is then assigned one of the following standards. There are seven minimum Program requirements (MPRs), eight parameters and a maximum of 110 points divided into 7 major categories.

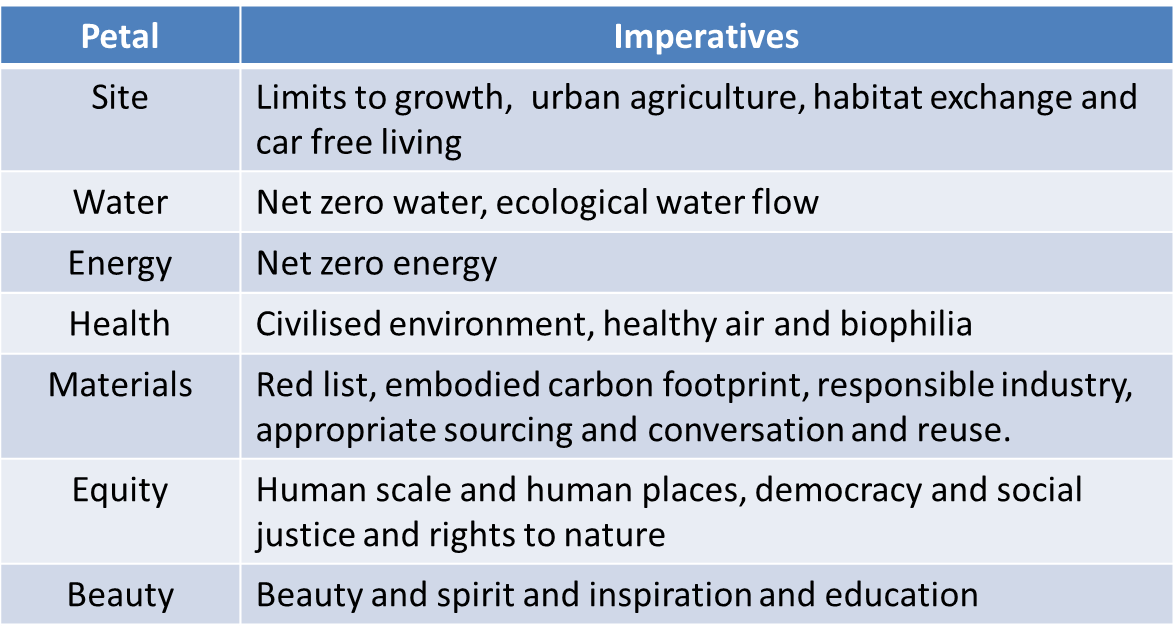

The Living Building Challenge (USA)

This assessment systems was developed jointly by both the USGBC and the Canada Green Building Council and currently has >70 registered buildings pursuing certification. The Living Building Challenge is based on a few simple but very powerful concepts, among them that a building should produce as much energy as it consumes, provide all the required water, and process all its sewage. The LBC is is based on seven performance areas (or petals) and the project must meet all of the imperatives to gain adequate points for certification.

1.2. Green Star

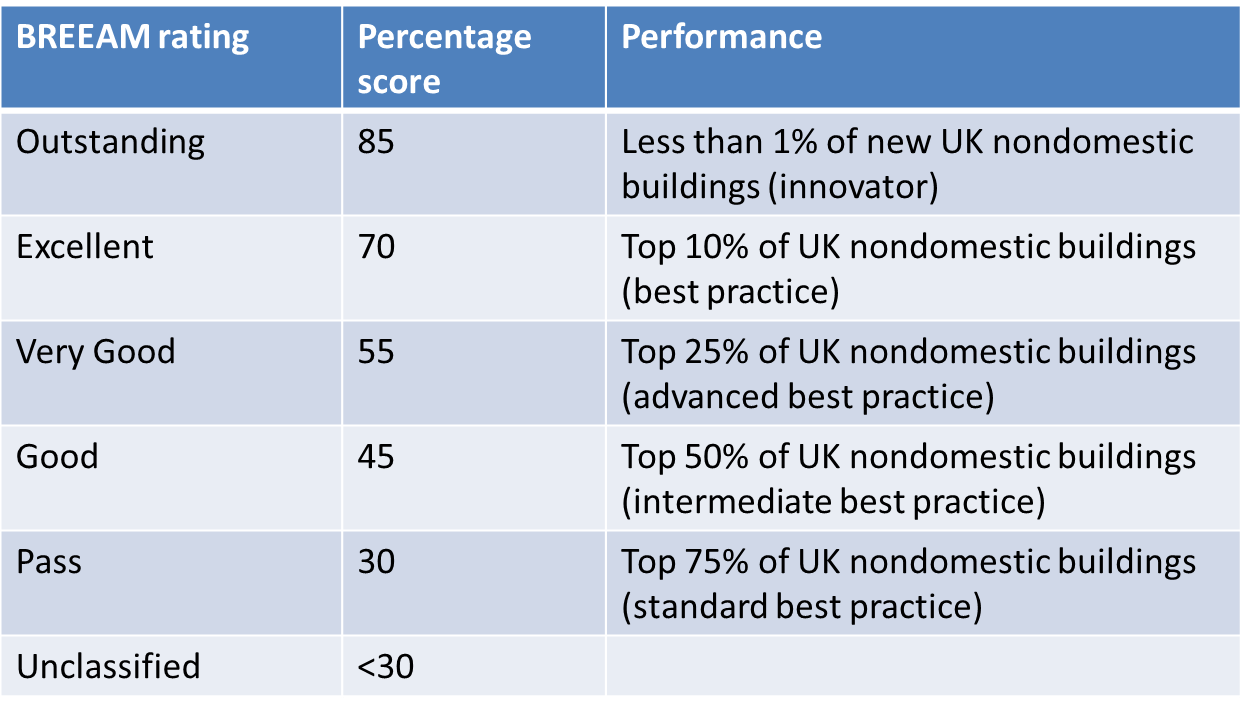

BREEAM (UK)

Building Research Establishment Environmental Assessment Method for buildings (BREEAM) is a UK based initiative. This is an assessment system designed to describe a building's environmental performance. BREEAM sets the standard for best practice for sustainable building performance in the UK. This can be used to rate any type of building and also for new constructions. This assessment consists of 49 individual assessment issues spanning 9 environmental categories. The categories include management, health and well-being, energy, transport, water, materials, waste, land use and ecology, pollution and innovation. Each of the categories has a different rating with energy having the top ranking of 19% and water the lowest at 6%.

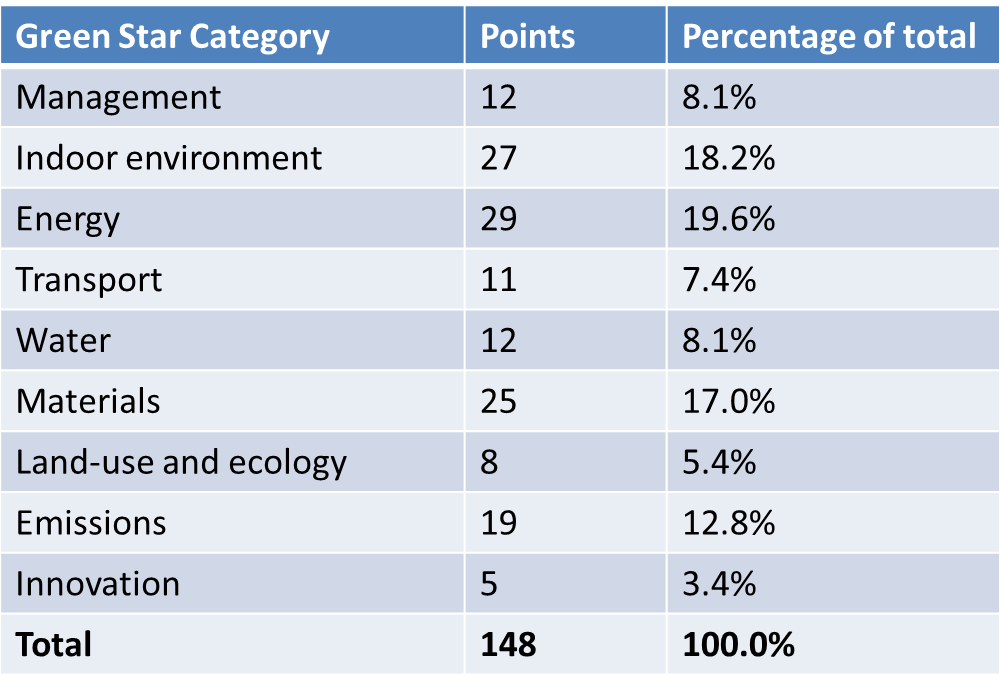

Green Star (Australia, NZ & SA)

Green Star is the major Australian green building assessment scheme and is similar in approach and structure to BREEAM. This assessment system awards from one to six green stars but only those buildings with ratings of 4+ stars are consider to indicate high performance. Nine categories are assessed in a Green Star rating and the number of green stars awarded is based on the percentage of total points available.

As globally, there is no single approach to assessment of buildings, the use of Life Cycle Analysis of materials and operating impacts is a more recent improvement for a holistic approach.

1.3. Construction & Building Materials

One of the issues with our ever-expanding use of chemicals is the identification of "safe" alternatives. Since 1930's, more than 100 000 new chemical compounds have been developed and insufficient information exists for health assessments of 95% of chemicals in the environment (World Watch Institute, 1998). In addition to this, there are approximately 80 000 chemical substances and technical mixes produced globally (each of which produces 5+ by-products). Of these chemicals, only 3000 have been studied for effects on living systems.

One of the issues with our ever-expanding use of chemicals is the identification of "safe" alternatives. Since 1930's, more than 100 000 new chemical compounds have been developed and insufficient information exists for health assessments of 95% of chemicals in the environment (World Watch Institute, 1998). In addition to this, there are approximately 80 000 chemical substances and technical mixes produced globally (each of which produces 5+ by-products). Of these chemicals, only 3000 have been studied for effects on living systems.

Here is an example of how alternatives may not always be the safe option. In 2005, the European Union (EU) banned the use of asbestos from brake pads in cars. As a result, many companies, including Ford and Volkswagen, replaced the asbestos with antimony sulphide (Sb2S3). NOAEL for asbestos in rats (oral) for 15 months exposure time is 2500 mg/kg/d whereas over just a 10 day period, the NOAEL for rats (oral) for Sb2S3 is 273 mg/kg/d. From this data, which of the compounds do you think is the safe alternative ? These and many other environmental issues are discussed in the book "Cradle to Cradle, re-making the way we make things " by Braungart and McDonough, highly recommended reading for this course.

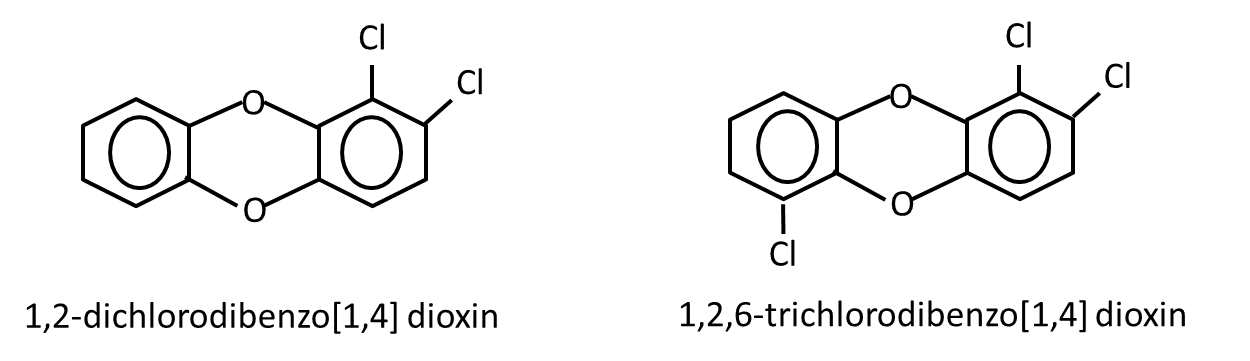

When considering materials for use in the building industry, it is important to address both the toxicity during production and disposal of the material. Dioxins and furans are two types of chemical compounds which are common by-products of many industrial processes which evolve chlorine. These organic compounds are both highly toxic and are able to bioaccumulate within biota. Research undertaken on dolphins in the North Pacific Ocean discovered levels of dioxins and furans between 13-37 million times higher than those found in seawater (Thorton, 2000)

2. Green Materials

How can we make the correct decisions about material choice ? Green building materials are "those that use the Earth's resources in an environmentally responsible way" (Speigel & Meadows, 1999). The desired characteristics of materials and products to be used in green buildings include:

- High recycled content

- reused building materials

- Locally/regionally sourced products

- Certified wood products

- Wood products made from rapidly renewable resources

However, problems in materials selection occur when we try to prioritise these attributes and also when we include the fate of the material at the end of its service.

There are no clear guidelines as to the criteria for "green" materials. This may simply mean that the product is locally sourced or may consider the potential indoor air quality from a material's emissions as measures. In some countries, Ecolabels may be used to designate them as being preferable on the basis of consensus standards that address each type of building product, e.g Blue Angel, Germany. The ecolabel "Blue Angel" has been applied on 11500 products, covering 90 different categories. This classification means the efficient use of fossil fuels, the reduction of GHG emissions and a reduction of the consumption of non-renewable raw materials. This classification is reviewed every three years. In Germany alone, there are currently 99 different ecolabels (click here for link) with a fairly diverse yet environmental focus.

The use of an ecolabel implies the respect for a set of environmental procedures dependent of each product, e.g. construction steel with the ecolabel must contain 50% recycled materials. Generally, ecolabels do not provide information about the impact of transportation and therefore do not provide a comprehensive environmental assessment.

The use of an ecolabel implies the respect for a set of environmental procedures dependent of each product, e.g. construction steel with the ecolabel must contain 50% recycled materials. Generally, ecolabels do not provide information about the impact of transportation and therefore do not provide a comprehensive environmental assessment.

Ecolabels have been in existence for 30 years and offer a quick assessment of environmental performance. However, they are not as comprehensive as Life Cycle Analysis (LCA) and have not been well adapted. One current disadvantage of these schemes is the small range of products currently covered which makes fair comparisons difficult. LCA is a tool which provides information about a product from its manufacture to its disposal, including resources used and emissions generated. The LCA process generally puts a greater emphasis on the reduction of energy with a climate change focus. Other opinions may focus more on recycling products regardless of energy inputs.

2.1. Green Materials Exercise

Green materials may be the components of products which may be used in a building or may be stand alone units.

Green materials may be the components of products which may be used in a building or may be stand alone units.

Green building products are generally building components which are preferable to a number of alternatives. However, green building products may not necessarily be made of green material products.

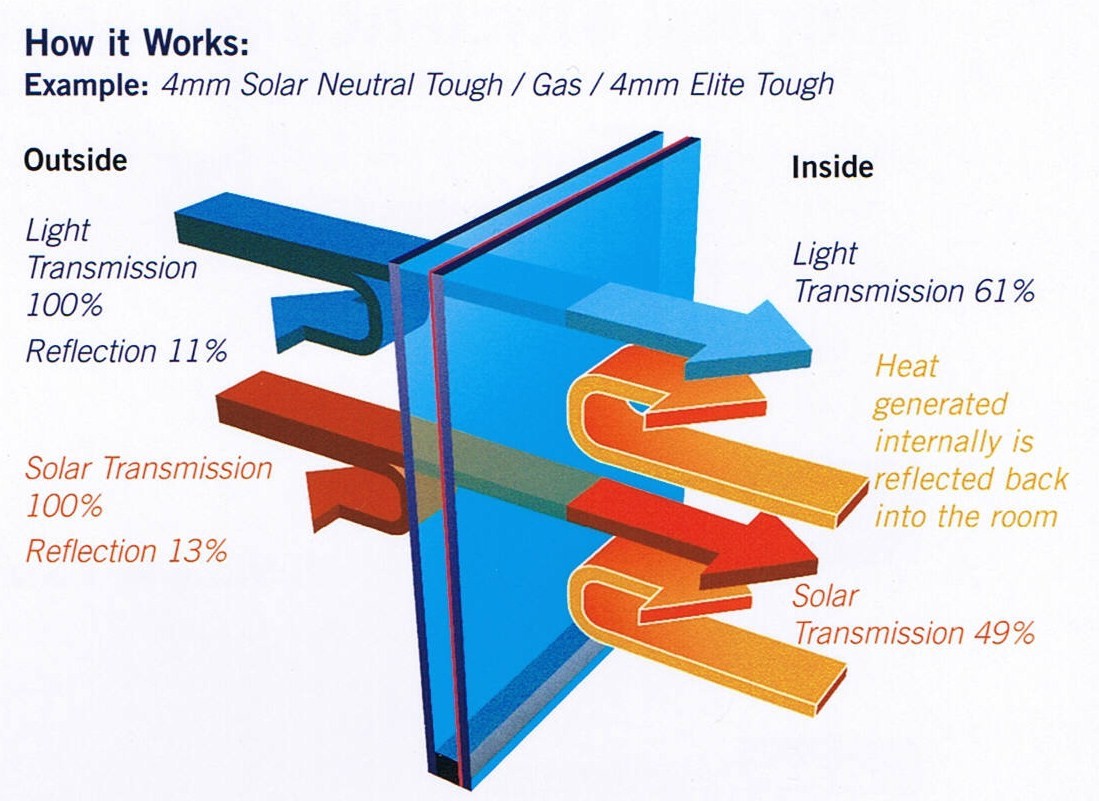

As an example: Low-emissivity (low-E) glass is a product which allows visible light to pass through it but reflects a large proportion of the heat-producing infrared wavelength light. It is chosen because of its energy performance, however the glass may be difficult to recycle due to the special films glued to the glass. Is this a better product than normal glass ? Another example is the use of photovoltaic panels for solar energy capture. What is the environmental impact of producing, maintaining, operating and disposing these units? - see here for a scientific opinion.

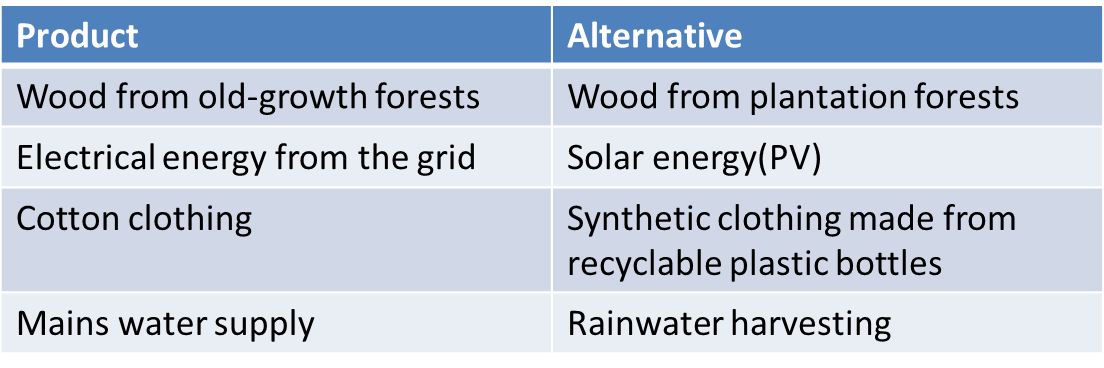

Using the table below, compare the products and their alternatives in terms of a comprehensive environmental cost.

2.2. EPDs and EBDs

An Environmental Product Declaration (EPD) is a particular type of LCA which provides environmental information in a common format, based on common rules, known as Product Category Rules (PCR). "EPD's offer an international standard of communication to objectively compare and describe a product's environmental impact throughout its entire life cycle from cradle to grave" (NSF Sustainability, 2014). PCR (according to ISO 14025) defines which data is used in a life cycle analysis and how the data is collected and reported. LCA analyses the data specified in the PCR. LCA measures inputs, outputs and environmental impacts of a product across its lifespan. The EPD provides a summary document of data collected in LCA. These enable comparison of a category of a products on environmental impacts. This can then be verified by a 3rd party.

The creation of EPDs has improved the process of determining the impact of a product. Environmental Building Declarations (EBDs) consider the impact of the whole building on the environment. Both EPDs and EBDs are similar to a nutritional label on food products in that they provide a method for environmental comparison. Initial reluctance by manufacturers to provide this level of information is being overcome by market competition. EPDs offer comparison between products whereas EBDs allow trade off between systems in order to minimise total impact (Kilbert, 2013).

Table 1: Cost-benefit analysis of options for heating

| Example | Cost | Benefits |

| Improved heating | Additional insulation, triple-pane gas-filled windows | Reducing the size and mass of heating, ventilation and air conditioning components |

EPD's are created according to ISO standards for which the 14000 series of standards deal with environmental management. These standards can be applied worldwide and reflect international consensus on good environmental and business practice. These standards assess the environmental impacts of an organisation's processes, products and services. There are guidelines for how manufacturers provide information on the environmental aspects of their products (ISO 14020) which prevent the misuse of environmental labeling. EPDs are designed to allow comparison of environmental impacts between similar products. However, as there are no other EPDs for New Zealand manufactured ready-mix concrete products, no comparisons are possible (Jones, 2014).

2.3. EPD Example

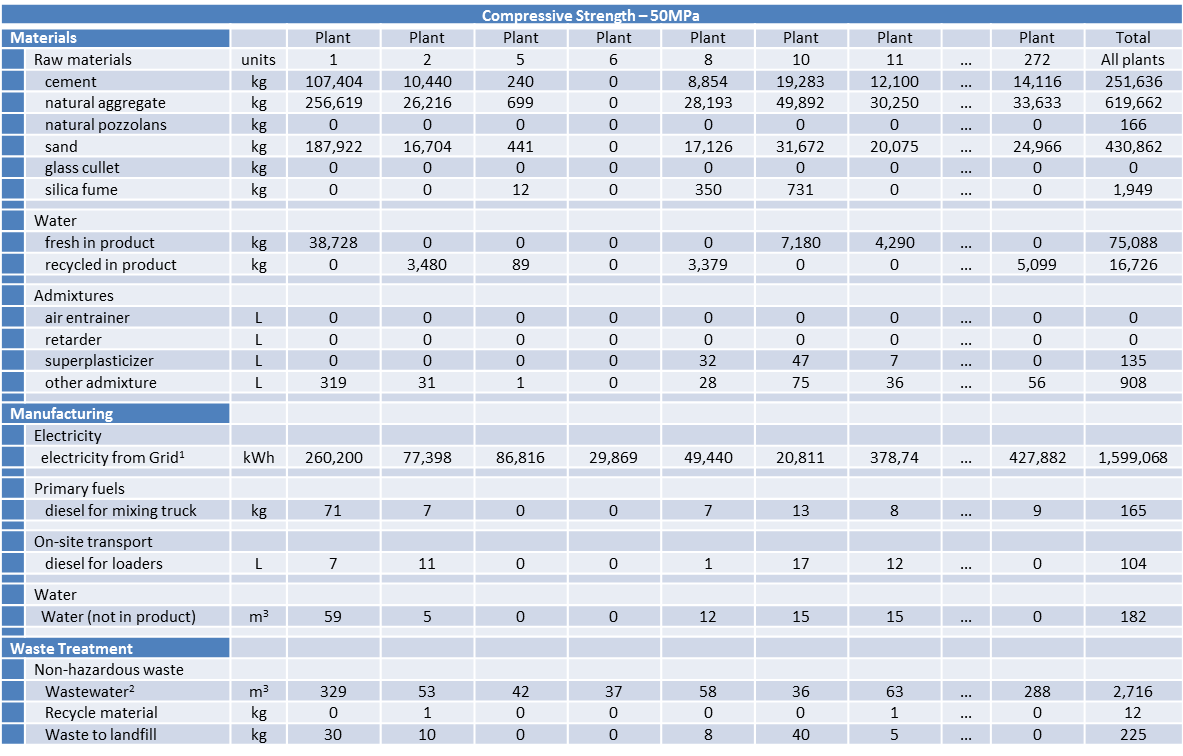

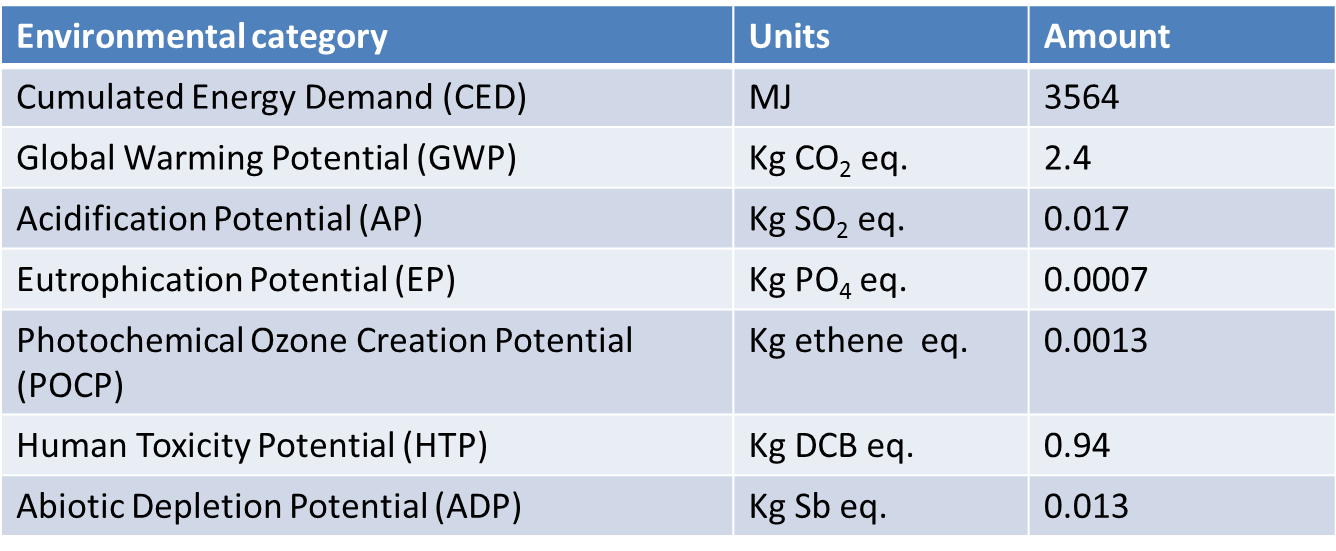

An EPD was developed for a New Zealand ready-mix concrete company in order to determine the environmental impact associated with the production of one cubic metre (m3) of normal grade ready mix concrete. The inventory information for one grade of concrete is displayed below.

Table 2: Batching plant material summary for 50MPa concrete

1Electricity values represent electricity used to manufacture all products, all compressive strength classes - not just 50MPa

2Wastewater values are for site - not just 50MPa

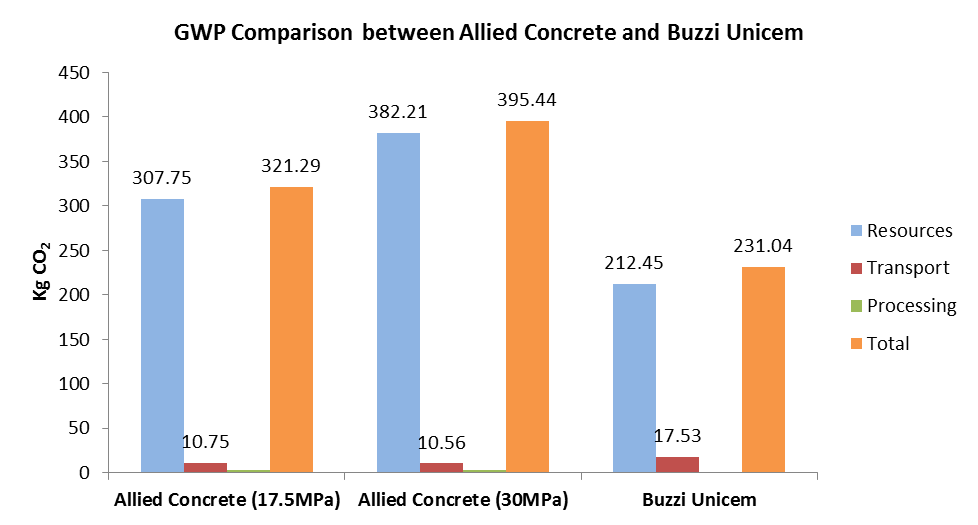

The figure below shows how EPD's can be used to compare the environmental impacts of similar products.

All data kindly provided by Jones, 2014

Click here for a link to another EPD example - site

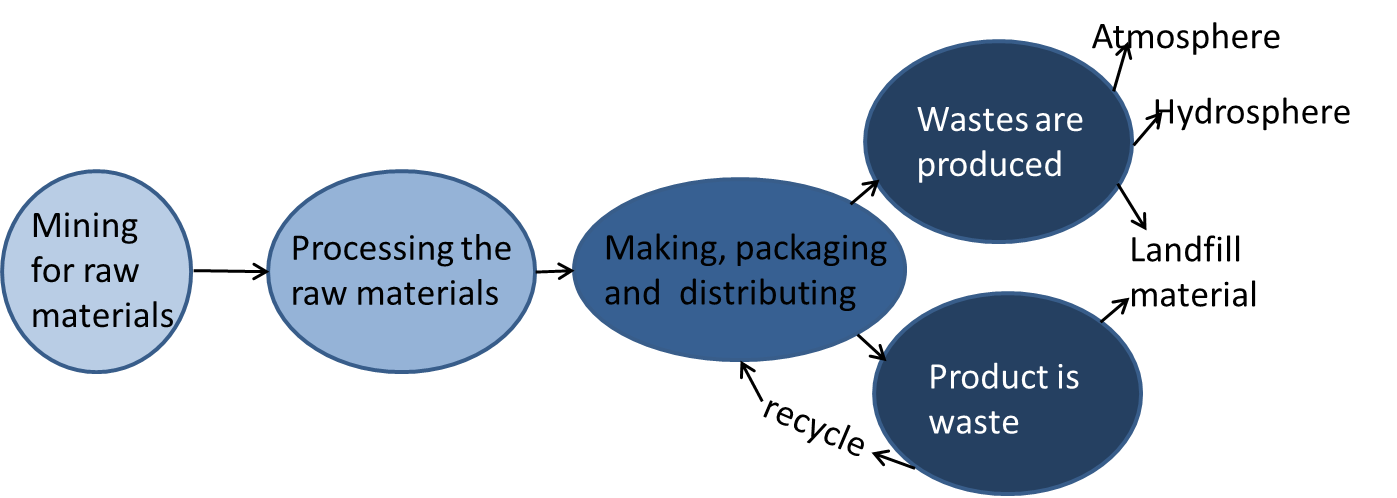

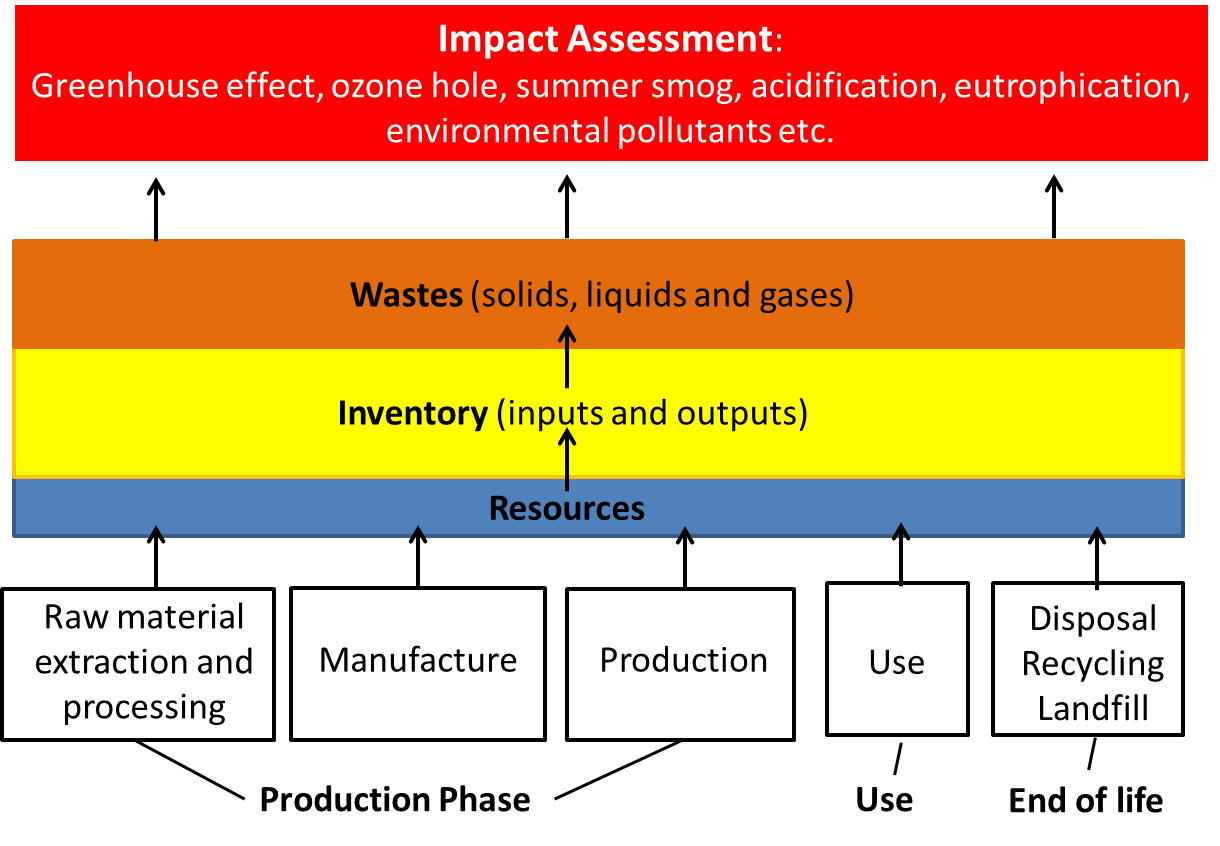

3. LCA

Life cycle analysis (LCA) is an environmental management tool increasingly used to understand and compare how a product or service is provided from "cradle to grave". The technique examines every single stage of the life cycle from raw material acquisition, through manufacture, distribution, use, possible reuse/recycling and then final disposal. In addition, every operation or unit process within a stage is included. For each operation within a stage, the inputs (raw materials, resources and energy and outputs (emissions to air and water and solid waste are calculated. Theses inputs and outputs are then aggregated over the life cycle. The environmental issues associated with these inputs are then evaluated in the Life Cycle Impact Assessment. This provides a general overview of the product system and other assessment tools can then be combined with this information to evaluate the product or service over the entire life cycle. (Image courtesy of sustainability.ualberta.ca)

Life cycle analysis (LCA) is an environmental management tool increasingly used to understand and compare how a product or service is provided from "cradle to grave". The technique examines every single stage of the life cycle from raw material acquisition, through manufacture, distribution, use, possible reuse/recycling and then final disposal. In addition, every operation or unit process within a stage is included. For each operation within a stage, the inputs (raw materials, resources and energy and outputs (emissions to air and water and solid waste are calculated. Theses inputs and outputs are then aggregated over the life cycle. The environmental issues associated with these inputs are then evaluated in the Life Cycle Impact Assessment. This provides a general overview of the product system and other assessment tools can then be combined with this information to evaluate the product or service over the entire life cycle. (Image courtesy of sustainability.ualberta.ca)

| Benefits | Limitations |

| Maps energy and material flows, resources, solid wastes and emissions for the total system and is therefore a complete systems map | It is not able to assess the actual environmental effects of the products, package or system (i.e it does not predict actual impacts or assess safety, risks or whether thresholds are exceeded) For example, cannot distinguish between diffuse and point source emissions. |

| Considers all environmental issues equally | Time consuming |

| Provides an objective basis for decision making | Does not take into account the potential for environmental disasters due to raw materials extraction (e.g a product created from power generated by Chernobyl) |

3.1. The process

LCA is a process that can be implemented to select the building materials. assemblies, systems and strategies which have the least impact on the environment. LCA can provide a method for understanding and quantifying both the financial and environmental costs associated with building. When used in the early stages of building, LCA is an effective way to reduce design and construction costs as well as provide a sustainable solution.

The LCA of building and building materials considers whole building effects such as the overall environmental impact of heating, insulation, and ventilation, flooring, painting and finishing materials. The following types of questions may be addressed in a LCA:

- What can we do to decrease energy use

- Which window type will help most with energy conservation

- How many times will this window be replaced over the lifetime of a building ?

- Which materials are less toxic?

- How will these materials be manufactured and disposed of ?

- Does it make sense to design the building for deconstruction when its life is over ?

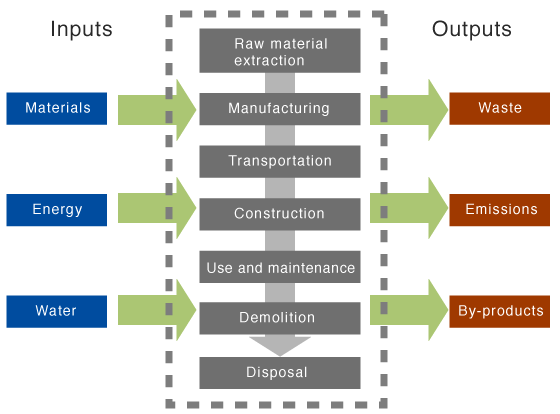

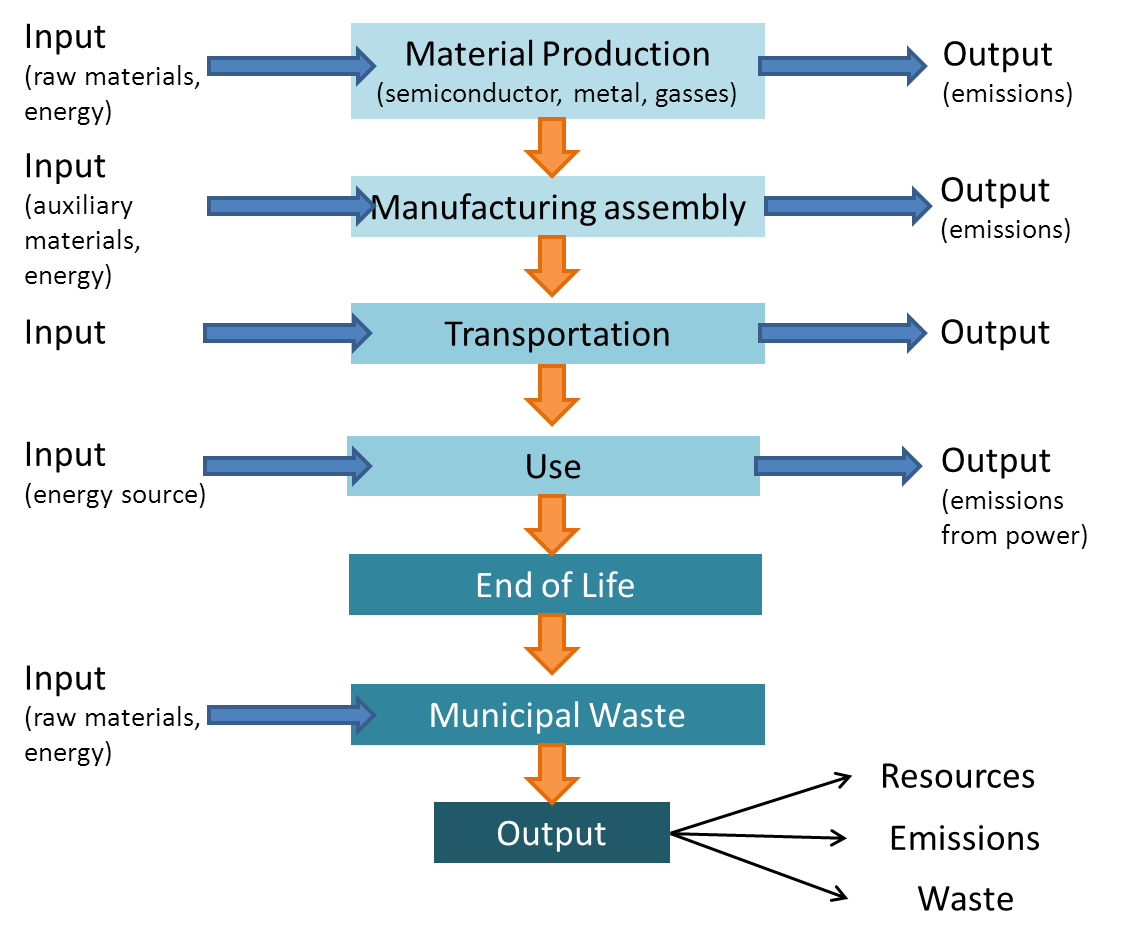

The following diagram shows the life-cycle factors of product manufacture (adapted from Keeler and Burke, 2009).

"LCA includes the complete life cycle of the product, process or activity, i.e the extraction and processing of raw materials, manufacturing, transportation and distribution, use, maintenance, recycling, reuse and final disposal" Setac, 1993.

3.2. Methodology

LCA evaluates the full environmental burden of a material, building assembly, system or service over its full lfecycle.

LCA evaluates the full environmental burden of a material, building assembly, system or service over its full lfecycle.

For example, if we were considering a LCA of a solar panel for a residential property we would need to consider the following issues:

- The raw materials that its made from. Where and how was the solar panel produced ?

- Packaging and transportation to its destination

- Installation requirements and any wastes produced.

- Operational and maintenance costs

- Disposal or recycling

- Disassembly and reuse

Image courtesy of www.thegreenestdollar.com

Impacts may be difficult to analyse and quantify but still the LCA can be useful for comparing the environmental impacts of different products.

According to ISO standardisation guidelines ISO, 1997a, ISO, 1997b, ISO, 1998a and ISO, 1998b, an LCA study can be divided into four steps:

- Goal and scope definition,

- Inventory analysis,

- Impact assessment, and

- Interpretation

(Hujibregts et al. 2000).

3.3. Goals & scope

This provides the aim and the subject of an LCA study and in addition, a ‘functional unit’ is defined.

An example of a functional unit is ‘watching 100 h of television’ with, for instance, the aim to compare the environmental impacts of different types of television sets. In the inventory analysis, all extractions of resources and emissions of substances attributable to the studied functional unit are listed (Huijbregts et al. 2000).

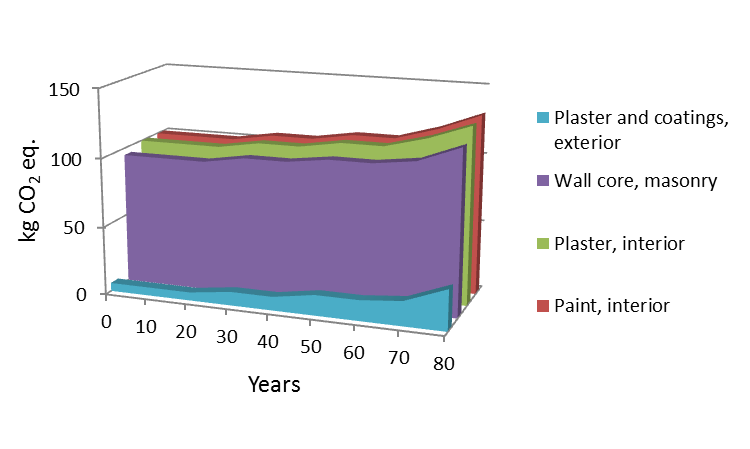

Within the building industry, a suitable functional unit may be 1m2, applied over the full area on any substrate. It is only with the definition of a functional unit and a comparison of similar duty over a similar timescale that comparable analyses of life cycle costs and life cycle assessments be worthwhile (Konig et al.2010). The image below shows a comparison of external wall coatings over a period of 80 years in terms of a global warming potential indicator, figure reproduced from Konig et al. 2010.

An example goal or scope may state: "To compare the impacts from extraction to end of life of installing fibreglass insulation made from recycled bottles compared with wool based insulation treated with boron"

The LCA study focus may be:

- Well to wheel

- Cradle to grave

- Cradle to gate

- Cradle to cradle

How would you define each of these scopes ? Which option do you think is most appropriate for sustainable solutions ? Cradle to cradle design is a well-documented idea from Mcdonough and Braungart. They have produced two books on this subject "cradle to cradle" and "the Upcycle" which are well worth reading. In addition, they have a web-site which has a focus on the building industry - follow link.

3.4. Inventory Analysis

This is the data gathering step and in particular gathering data about materials that cause environmental effects. It is important to consider effects that are both directly and indirectly attributable to the life cycle of the product, for example, the production of the materials which drive solar panels (which include monocrystalline silicon, polycrystalline silicon, amorphous silicon, cadmium telluride, and copper indium gallium selenide/sulfide) should also be considered as they may have an environmental impact which is indirect to the life cycle of the panel itself.

Total flows are examined including resources used (inputs) and all wastes produced (outputs).

Image reproduced from Konig et al. 2010.

3.5. Inventory units

Data from the inventory can be used to create a number of indices. Indices are calculated in order to be able to interpret the results of the inventory sensibly (see table below) Some areas of the inventory may be found to have no direct effect on the environment. For example, if a resource is used for which the supply is plentiful then only energy consumption for extraction and manufacture may create environmental effects. As the availability of this resource decreases then the cost of exploiting this resource increases (Konig et al.2010).

| Indice | Description | Unit |

|

Non-renewable primary energy consumption |

Use of finite biotic energy resources, e.g. natural gas, oil, lignite, coal and uranium | MJ |

|

Renewable primary energy consumption |

Energy from wind and water, geothermal, solar and biomass energy | MJ |

|

Water use |

Aggregate value of ground and surface water | kg |

|

Use of natural space |

Includes both surface transformation and land use | m2per year |

| Waste | Often subdivided into (1) excavated and stockpiled waste (mainly mineral wastes or soils) (2) domestic & commercial waste and (3) special waste (inc. hazardous materials) | Various |

3.6. Impact assessment

The first step in this process is to consider and list the impact categories. For example, if the production and use of your product requires energy, then climate change would be an impact category. If a toxic chemical was used during manufacturing then human health would be an impact category. Impact categories may correspond with environmental problems, such as human toxicity or ozone depletion. Common categories include:

The first step in this process is to consider and list the impact categories. For example, if the production and use of your product requires energy, then climate change would be an impact category. If a toxic chemical was used during manufacturing then human health would be an impact category. Impact categories may correspond with environmental problems, such as human toxicity or ozone depletion. Common categories include:

- Global warming potential (expressed as CO2 equivalents and usually with a timescale provided , 100 years is commonly used (GWP 100)).

- Ozone depletion potential (ODP) in the stratosphere (expressed as R11 (or trichlorofluoromethane) equivalents.

- Acidification potential (AP) (expressed as SO2 equivalents)

- Eutrophication potential (expressed as PO4 equivalents)

- Photochemical ozone creation potential (POCP) (expressed as C2H4 equivalents)

- Abiotic resource consumption (expressed as Fe equivalents)

- Human and ecotoxicity potentials, these are often difficult to establish as there are no models that can be applied uniformly to all classes of substances. It is also necessary to consider the relative risk and exposure to biota.

Other categories may include water consumption, Smog formation potential, waste production, land use, air pollution and alteration of habitats. The importance of each category will be different for each region or country. There are several tools available that use LCA, e.g. BEES (Building for Environmental and Economic Sustainability). These tools may specify different environmental categories, e.g. indoor air quality.

Image courtesy of greenspec.co.uk

After this step, the magnitude of the potential impact of individual substances within each impact category is determined.

The green guide (www.thegreenguide.org,uk)- example

Integrated Material Profile and Costing Tool (IMPACT) click here

3.7. Interpretation

For this stage of the Life Cycle Assessment, ISO 14040 requires the results of the inventory and the impact assessment to be evaluated with the aim of deriving conclusions and providing recommendations. There are three phases of the interpretation stage:

- identify of the critical parameters from the inventory and impact assessment (i.e which processes make the largest contribution to an indicator)

- Assess completeness and data quality

- Provide conclusions (including limits of applicability)

(Konig et al, 2010)

One of the disadvantages of the LCA is that technical, societal and economic matters are not addressed.

3.8. LCA for Buildings

In the life cycle assessment of buildings, the overall result is strongly influenced by both the assumed service life and the life cycle phase of the building. At the early planning stage, fundamental design changes can be made, however at a later stage (e.g detailed design or during construction), changes are more difficult to implement.

To determine the functional unit, the function and form of construction of the building must be described. Parameters which should be identified include:

- Location and integration into the environment

- Building type

- Volume and areas

- Type of construction

- Type and intensity of use

- Assumed life service

At the concept stage, a dominance analysis can identify crucial contributors in the life cycle from which routes for optimisation can be established. There is much uncertainty at this stage, in terms of design, construction and material choice. Mean data for materials, material groups or forms of construction are best used for life cycle estimates. During the detailed design, less changes are possible however components which have a large impact may be modified. After completion, documentation of ecological performance and monitoring are necessary. Is the design successful ? These results should be assessed for reliability with likely errors identified. The life cycle assessment should follow the principles of ISO 14040 and 14044 and may include:

- Building use (energy and resource use)

- Deconstruction, recycling and disposal

- Life stage, e.g. production, use and end of life

"As well as all the materials used in the construction of the building, the life cycle assessment must also cover all the relevant processes of energy provision (e.g for heating, air conditioning and ventilation)" Konig, 2010.

3.9. LCA findings

Some interesting findings as a result of LCA for buildings have been summarised below:

- When wooden houses were compared to concrete houses, the overall environmental impact was 21% greater for concrete (Gerrilla et al. 2007)

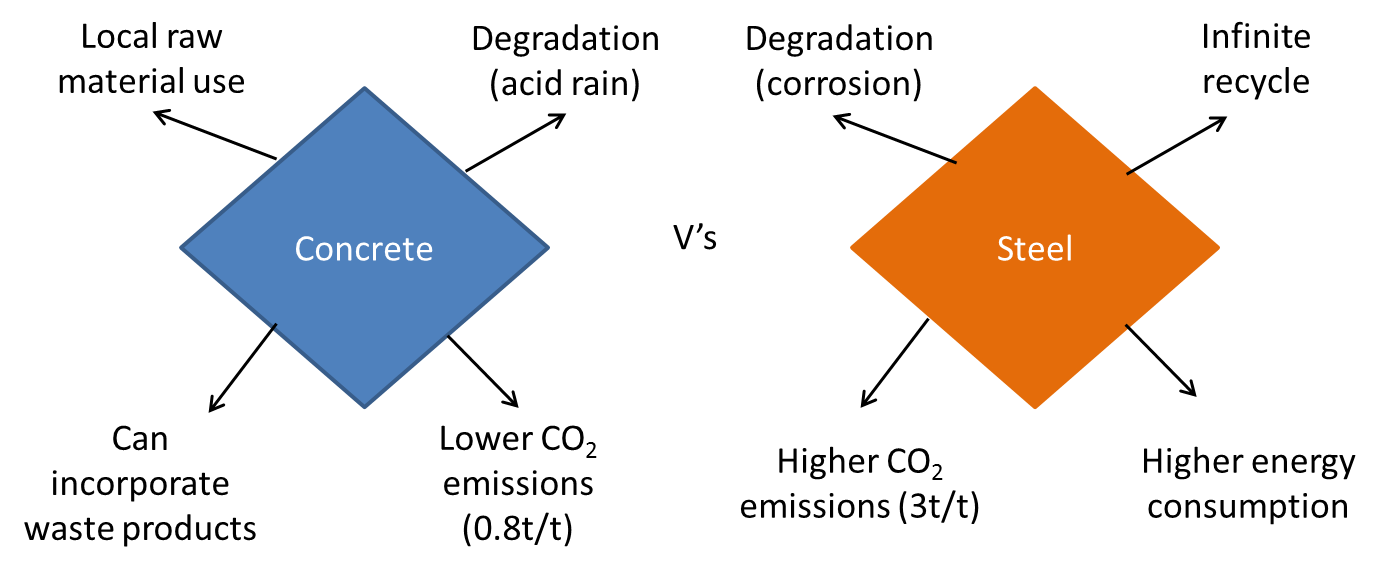

- Steeel structures for offices consume 75% energy and produces 50% of the GCG emissions compared to reinforced concrete. However, operationally the concrete structure had a much lower energy consumption making it more environmentally favourable (Xing et al. 2008)

- A comparison of concrete with and without recycled aggregates demonstrated that transportation has a greater environmental impact than the extent of recycling (Mannkovic et al. 2010)

- Best environmental performance for sound insulation was found to be recycled paper>rock wool>polystyrene (Desarnaulds et al. 2005)

- Environmental impact of ceramic tiles is 200% higher than marble tiles (Nicoletti et al. 2002)

4. LCA Case study - step 1

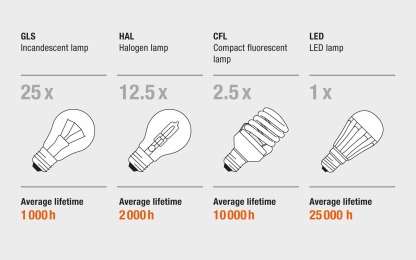

The following is an example of a step by step LCA to compare lightbulbs, LED v's incandescent. It is important to remember that LCA does not have to be comparative tool (i,e it is not always used to compare products). Please note that this has been highly simplified ! Many LCA can take years to create as there is much data to be considered many mathematical matrices to be used.

The following is an example of a step by step LCA to compare lightbulbs, LED v's incandescent. It is important to remember that LCA does not have to be comparative tool (i,e it is not always used to compare products). Please note that this has been highly simplified ! Many LCA can take years to create as there is much data to be considered many mathematical matrices to be used.

Step 1

Decide on a functional unit so that the comparison is fair. For example, you should not consider two substances measured in different units. If one product is solid and another liquid, it would not be feasible to compare on a unit by unit basis but you could use a mass unit, e.g kg or g. Make sure that the unit will work well for all products (i.e don't choose a unit which is too large or too small for the majority of the products).

In this example, we can use the lightbulb as a unit but if we are comparing two similar products then we should apply boundaries to this. For example, it is fair to compare a 100W halogen bulb with a 100W incandescent bulb ? This example uses the luminous flux of all exams between 345-420 lumens. The comparison is therefore made between 40W incandescent and 8W LED bulbs. Also specified is reference parameter of a lifetime of 25 000 hours. For an incandescent bulb, this will be the equivalent of 25 lamps whereas for an LED lamp, this is just one unit.

4.1. Step 2 - Goal & Scope

Step 2

Draw the life cycle of the product from cradle to grave. This can be a simple flow diagram as shown below.

Figure adapted from Osram, 2009.

4.2. Step 3 - Impact Assessment

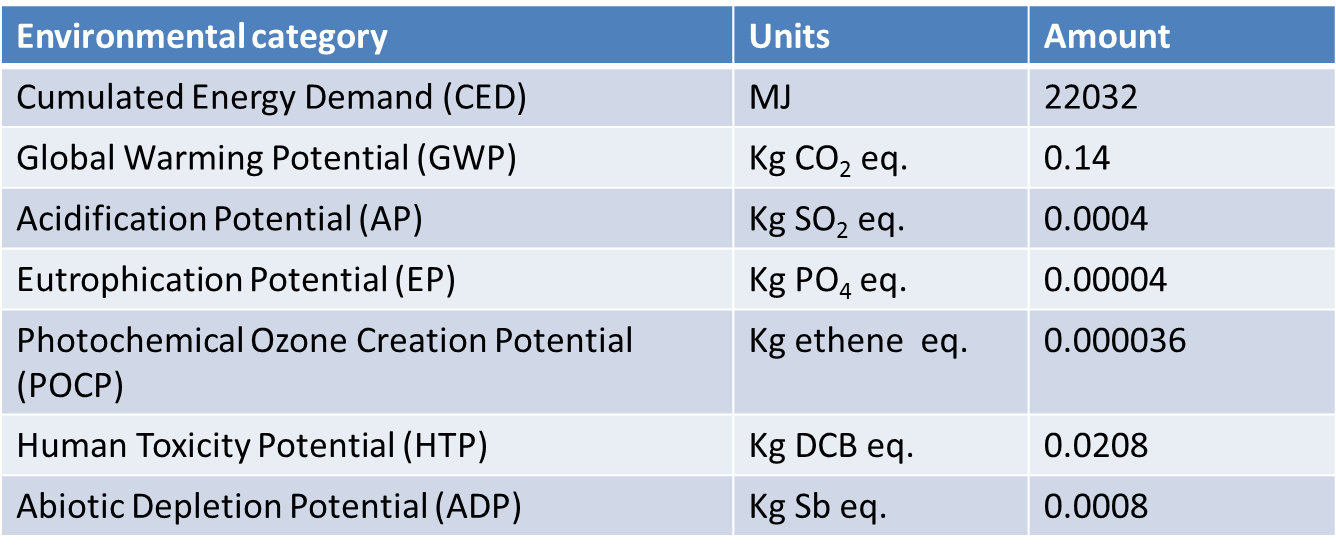

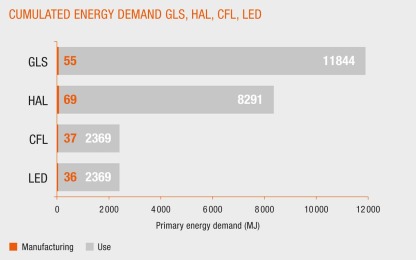

Assessments are made according to each of the environmental categories. Below are the environmental assessments for incandescent and LED lightbulbs.

Table 1: Impact Assessment for incandescent lightbulbs (reproduced from Osram, 2014)

Table 2: Impact Assessment for LED lightbulbs (reproduced from Osram, 2014)

4.3. Step 4 - Interpretation

Each LCA would be interpreted (according to ISO 14040) individually, for the incandescent lightbulb, the following interpretation was made.

Each LCA would be interpreted (according to ISO 14040) individually, for the incandescent lightbulb, the following interpretation was made.

"For the calculation of the CO2 emissions resulting from the use phase, an electricity mix of 0.55 kg CO2 per kWhEl was taken as a basis. Electricity production during use is also responsible for other environmental impact categories, but this depends very much on where the lamp is used. Equally depending on the electricity mix, the usage of an incandescent lamp may be responsible for mercury emissions. This is due to the comparatively high ratio of coal power plants in some electricity mixes, which emit mercury by burning lignite or hard coal to produce electricity". Osram, 2014

This may be followed by comparisons of similar products (such as different lightbulb types as in this case). In terms of primary energy demand, the majority of the energy was required during the user phase (98.5-99.5%) with a relatively insignificant energy requirement during manufacturing and other life cycle stages. As energy consumption was deemed to have the greatest environmental impact, this was used as a comparison. From the data below, it can be observed that the incandescent bulbs have the greatest impact due to its energy demand.

(Data courtesy of Osram, 2014)

5. The Natural Step

The Natural Step is a tool developed to assess sustainability as guidance for building materials, products and design by Dr Karl-Henrik Robert in 1980's. These conditions may be simplified to the following:

The Natural Step is a tool developed to assess sustainability as guidance for building materials, products and design by Dr Karl-Henrik Robert in 1980's. These conditions may be simplified to the following:

- In order for a society to be sustainable, nature's functions and diversity are not systematically subjected to increasing concentrations of substances extracted from the Earth's crust. In practical terms, this includes metal/mineral recycling and a decreased economic dependence on fossil fuels.

- In order for a society to be sustainable, nature's functions and diversity are not systematically subjected to increasing concentrations of substances produced by society. Society needs to find ways to reduce economic dependence on human-man substances such as DDT, PCB's and other synthetic or ozone depleting compounds.

- In order for a society to be sustainable, nature's functions and diversity are not systematically impoverished by over-harvesting or other forms of ecosystem manipulation. In practical terms, do not deplete resources or produce waste at a rate which is faster than nature's capacity to produce resources/recycle waste.

- In a sustainable society, resources are used fairly and efficiently in order to meet basic human needs globally. Global fairness is essential for social stability and the cooperation needed to achieve steps 1-3. To achieve step 4, humanity must strive to improve technical and organisational efficiency around the World and to use fewer resources, especially in affluent areas.

5.1. Practical Solutions

The Natural Step provides a sound philosophy for the approach to green materials, however in practical terms, these materials may be difficult to identify, difficult to source and cost prohibitive. An alternative approach may be to follow the guidelines provided by the Environmental Building News (EBN) which are divided into five categories as follows:

The Natural Step provides a sound philosophy for the approach to green materials, however in practical terms, these materials may be difficult to identify, difficult to source and cost prohibitive. An alternative approach may be to follow the guidelines provided by the Environmental Building News (EBN) which are divided into five categories as follows:

1. Products made from environmentally attractive materials

- Salvaged products

- Products with postconsumer recycled content (image hotel made with recycled bottles www.environmentteam.com)

- Products with postindustrial recycled content

- Certified wood products

- Rapidly renewable products

- Products made from agricultural waste material

- Minimally processed products

2. Products that are green because of what is not there

- products that reduce material use

- Alternatives to ozone-depleting substances

- Alternatives to products made from PVC and polycarbonate

- Alternatives conventional preservative-treated wood

- Alternatives to other components considered hazardous

3. Products that reduce environmental impacts during construction, renovation or demolition

- Products that reduce the impacts of new construction

- Products that reduce the impacts of renovation

- Products that reduce the impacts of demolition

4. Products that reduce the environmental impacts of building operation

- Building products that reduce heating and cooling loads

- Equipment that conserves energy

- Renewable energy and fuel cell equipment

- Fixtures and equipment that conserve water

- Products with exceptional durability or low maintenance requirements

- Products that prevent pollution or reduce waste (try these - link)

- Products that reduce or eliminate pesticide treatments

5. Products that contribute to a safe, healthy indoor environment

- Products that do not release significant pollutants into the building

- Products that block the introduction, development, or spread of indoor contaminants

- Products that remove indoor pollutants

- Products that warn occupants of health hazards in the building

- Products that improve light quality

5.2. Materials selection

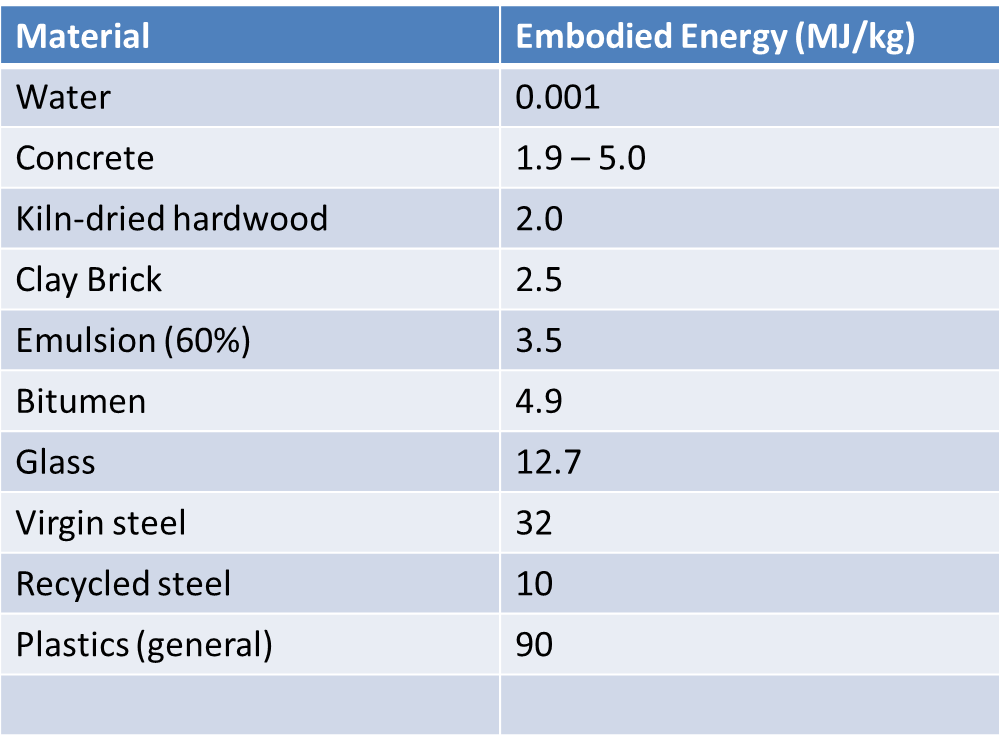

The sustainability of materials may be concerned from various viewpoints. For example, we are depleting our natural resources and producing waste materials which do not biodegrade easily. Many of the materials produce emissions of undesirable chemicals which may add to poor indoor air quality. Transportation involves energy consumption and has associated pollution produced. An approximate measure of the energy (pr unit mass) typically needed to produce a building product is known as its embodied energy. This is a more technical way of evaluating a materials but needs to include energy requirements for:

- Raw material acquisition

- Product manufacture

- Upstream energy use (e.g. construction and operation of factory)

The table shows some estimations for the embodied energy of some common materials (adapted from Means, 2011 and Rudman & Jenkins, 2012). Processes, such as recycling, become more important for products with higher embodied energy. This is however only part of the environmental picture and should be considered alongside a larger energy scenario. This scenario should include consideration of the climate, site, building design and life cycle as a whole system.

Other important factors associated with a material are its durability, reuse/recycling potential and the environmental impacts associated with its production, use and end of life (Means, 2011).

Minimising the environmental impacts of building materials means prioritising as demonstrated below:

- Reduce materials use (this may include the rejection of finishing touches which add aesthetically or may include designing for end of life deconstruction.

- Reuse existing structures (minimisation of new resource use by upgrading/renovating the existing structure.

- Use materials created from renewable resources (closing the material loop via organic recycling).

- Reuse building components (from deconstructed buildings

- Use recyclable and recycled content materials (this is often very difficult because only very few building materials are recyclable (e.g metals and plastics) without the loss of strength or durability.

- Use locally produced materials. However challenges arise when defining "local" and also some better longer lasting material may be rejected based on location.

Table adapted from KÖnig et al, 2010.

5.3. Green material research

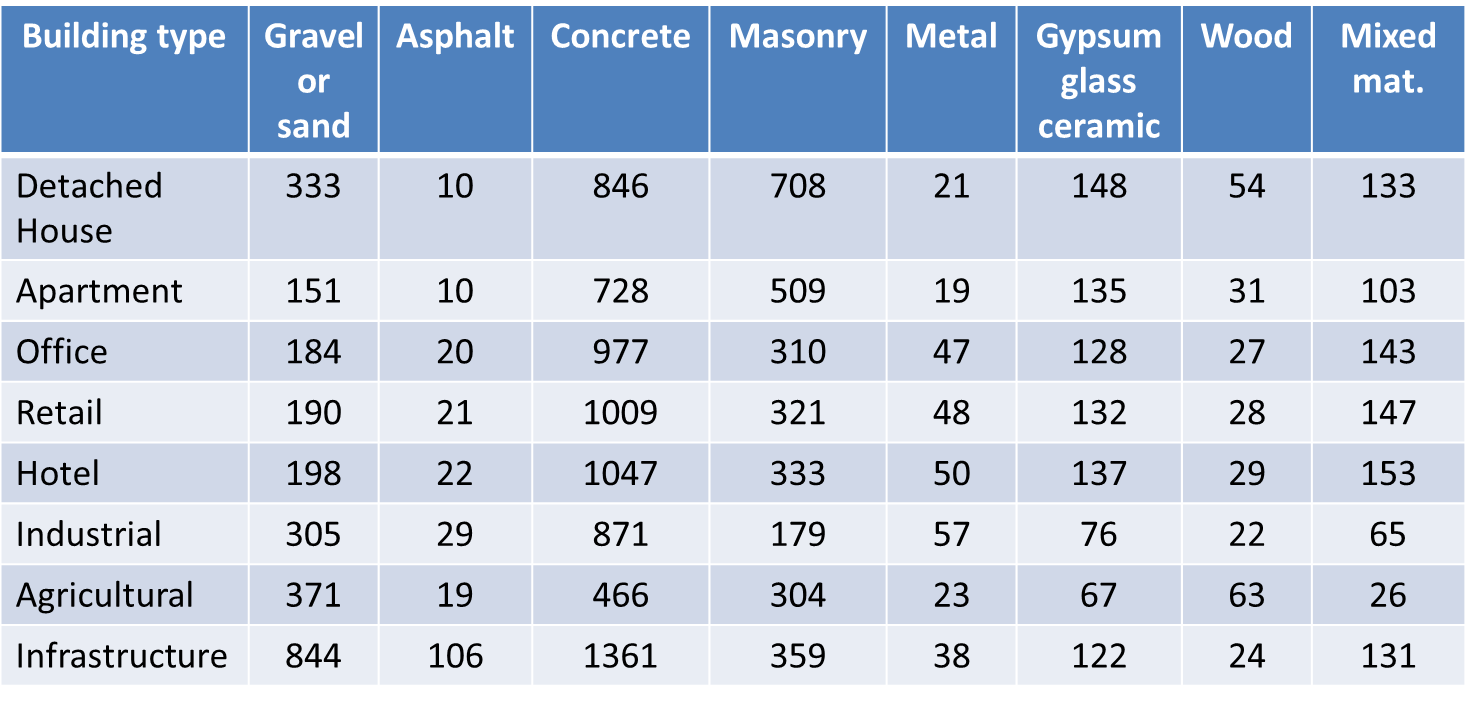

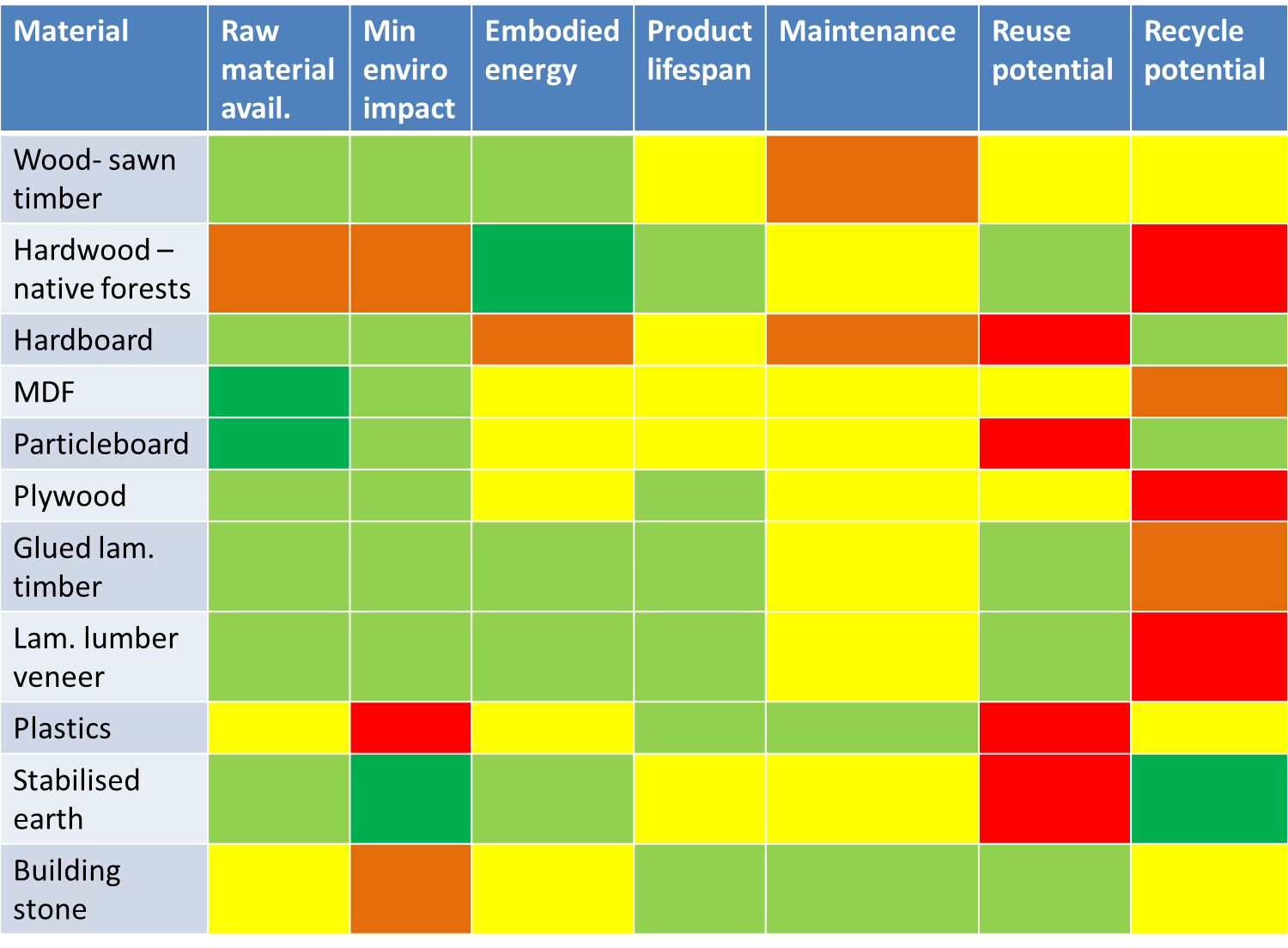

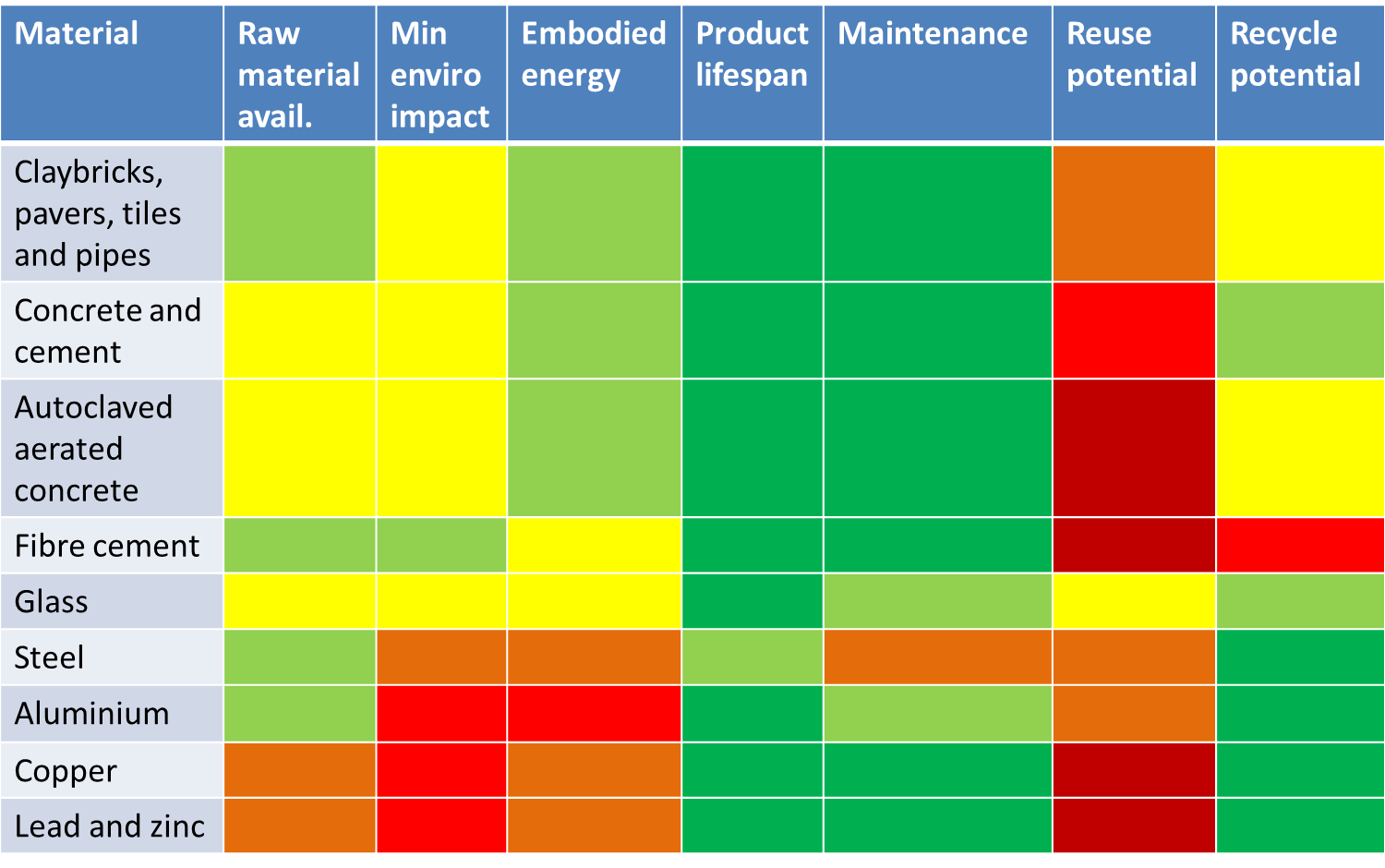

An Australian study of the environmental impact of many different building materials has been summarised in the table below (data from Lawson, 1996). Notes for table, (1) min = minimal in column 3, (2) Reuse potential (column 7) is for the product and not the material. Green = Excellent, pale green = very good, yellow = good, orange = fair and red = poor.

In summary, green building materials are those that:

- Produce a healthy indoor environment

- Do not contribute to an unhealthy outdoor environment

- Minimise building energy use

- Have low embodied energy

- Are durable, reusable, recyclable and/or biodegradable

- Are obtained locally

5.4. Occupant health

As well as the use of resources and waste production, a sustainable building should be able to "sustain" its occupant in terms of occupant health. Poor Indoor quality has been linked to illnesses such as sick building syndrome (SBS), building related illnesses (BRI) and multiple chemical sensitivity (MCS). Follow this link for further information. Emotional and mental well-being may also be important when considering the sustainability of a building. Improved daylighting is considered to be one effective solution and "International research shows improving the quality of the workplace boosts productivity and reduces sick days" (NZGBC, 2014). Image shows use of daylighting in the Geyser Building, Parnell (courtesy of idealog.co.nz). This is a relatively cheap and simple solution however it does not address indoor air quality which we will look at now.

As well as the use of resources and waste production, a sustainable building should be able to "sustain" its occupant in terms of occupant health. Poor Indoor quality has been linked to illnesses such as sick building syndrome (SBS), building related illnesses (BRI) and multiple chemical sensitivity (MCS). Follow this link for further information. Emotional and mental well-being may also be important when considering the sustainability of a building. Improved daylighting is considered to be one effective solution and "International research shows improving the quality of the workplace boosts productivity and reduces sick days" (NZGBC, 2014). Image shows use of daylighting in the Geyser Building, Parnell (courtesy of idealog.co.nz). This is a relatively cheap and simple solution however it does not address indoor air quality which we will look at now.

The quality of indoor air is dependent on numerous contaminants.generated from indoor sources as well as contaminants transported from outdoors via ventilation and infiltration. Most building construction materials and office furniture emit volatile organic compounds after manufacturing (any products) or after installation (wet products). With a few exceptions, such as products containing formaldehyde, the emissions of building materials decay considerably within the first few months after manufacture or installation. Other sources of indoor air pollutants occur on a more continuous basis and arise from clearing products and occupants and their activities.

5.5. Green solutions

Whilst adequate ventilation can dilute or remove contaminants, it can also provide a source of contamination if poorly maintained (e.g. dust or mold spores). Designing a watertight building which does not contain plumbing leaks can help to prevent mold formation. However good ventilation is an essential feature of houses situated in areas with high radon emissions (US EPA). Radon is a gas that occurs naturally from the breakdown—or the radioactive decay—of uranium. Exposure can occur through breathing outdoor air, in buildings and homes, and by eating or drinking (ingestion). Radon gas can seep through cracks in buildings and expose people to the radiation, which can lead to severe health problems. It is the second leading cause of lung cancer in the United States, estimated to be responsible for more than 20,000 lung cancer deaths each year (Centers for disease control and prevention, 2010).

Prior to building, an important factor in providing optimal indoor air quality is the most effective positioning of the property. Amongst other things, it is important to consider:

- active soil depressurisation and sealing of vapour intrusion routes to avoid radan contaminiation.

- Positioning buildings away from strong electromagnetic fields

- Position building intakes away and upwind from pollution sources (e.g motorways)